What do you do when you are faced with a challenging product development?

As one gains experience in the industry, one starts thinking that he/she has acquired a lot of knowledge to at least know about the product range in the industry and then comes a shocker that is humbling.

Having been in the rubber extrusion business nearly three decades, I, somewhere, started to have this feeling that I knew about the possible products in extrusion and different properties of rubber that can be manufactured and be practically useful, especially hardness property.

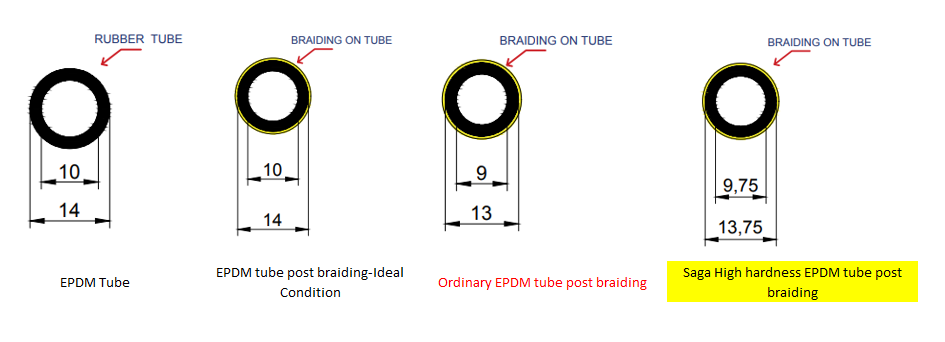

One day we got a requirement for an EPDM tube of 85 shore A hardness. I spoke with the customer fully convinced that there is some mistake in his specifications and that we can discuss this out to a useful hardness of 80 (my prejudice here in play).

The customer might have faced this situation with a lot of manufacturers and played it very coolly saying he will send a sample and we could check it ourselves. Upon checking the sample, we received, we were surprised to see that the tube had hardness of 87. And they needed sizable quantity of this specification on a regular basis.

Now started the challenge of manufacturing the same on microwave line. The customer was importing it and was in panic mode due to onset of COVID 19. This gave us a small window where he was ready to start working with 82 hardness as well assuming slowly, we would achieve the required hardness.

As we went deeper into the project, we realised the high hardness requirements were designed to withstand a specific pressure subjected to the tube to be used in a specific application. We faced a lot of issues as we went into trials for this high hardness extrusion as compound would scorch due to the extremely high heat generation and excessive loads on the extruder.

Team Saga kept consulting some of the fine rubber technologists, did a lot of research on compound and mixing, kept changing the recipe & taking trials. Finally, after a sustained & dedicated hard work of nearly 10 months, we have now been able to successfully make a compound which extrudes well and still gives a hardness of 85. I feel the key solution to this problem, or for that matter any problem is a combination of four important aspects- Clarity, Perseverance, Dedication, Transparency.

We kept complete transparency with the customer who has always been patient with us looking at the clarity we had, our perseverance & whole hearted efforts. The result of this is that the customer has approved our samples and we have started a mutually beneficial business relationship with this product. The customer is happy that he doesn’t have to depend upon imports & hence have peace of mind. Team Saga is happy that they have been able to overcome a challenge and develop a new product for their expansive portfolio.

I can say now that Team Saga has been able to develop products which are ranging from hardness levels 40 to 85 and still learning.

The key takeaways are

- Never stop learning & get complacent

- Keep your mind open for new challenges, developments, ready to innovate (Dedication)

- Keep trying till you succeed (Perseverance)

- Maintain transparency with customer (Involve customer in the developmental process)

- Confidence that we can “Make in India for World”

If you like this article and need more information or guidance, please feel free to get in touch. Team Saga is just a call/mail away.